Silicon tubes may not be the first thing that comes to mind when you think of essential purchases, but these versatile and uncomplicated items have a wide range of uses in various industries. Whether you need them for medical applications, automotive systems, or simple DIY projects, choosing the right silicon tube can make a significant difference. In this guide, we’ll walk you through 6 straightforward factors to consider when buying silicon tubes for inflatable seals manufacture. From the material’s quality to the size and intended use, these uncomplicated considerations will help you make the right choice and ensure that the silicon tubes you select are perfect for your specific needs.

1. Quality and Purity:

When it comes to silicon tubes, quality and purity are uncomplicated essentials. Depending on your application, you might need medical-grade, food-grade, or industrial-grade silicon tubes. These types of tubes differ in their purity and resistance to various substances. Ensure you select a silicon tube with the right level of quality to meet your specific requirements. For applications where purity is critical, such as medical or food-related uses, opt for tubes that meet the relevant standards for uncomplicated peace of mind.

2. Temperature Resistance:

Silicon tubes are known for their straightforward ability to withstand a wide range of temperatures. However, it’s essential to consider the specific temperature range you’ll be working with. Some applications require high-temperature resistance, while others involve extremely low temperatures. Ensure the silicon tube you choose can handle the temperatures you’ll encounter without degrading or becoming brittle. This uncomplicated consideration guarantees that your tubes will perform effectively in various conditions.

3. Flexibility and Durability:

The flexibility and durability of a silicon tube can vary depending on its composition and intended use. For applications where you need a tube to bend and twist with ease, such as in a medical device or a car’s engine, flexibility is crucial. On the other hand, if you need the tube to withstand pressure or abrasion, durability becomes a more uncomplicated priority. It’s important to strike a balance between flexibility and durability to ensure the silicon tube meets your specific requirements without any complications.

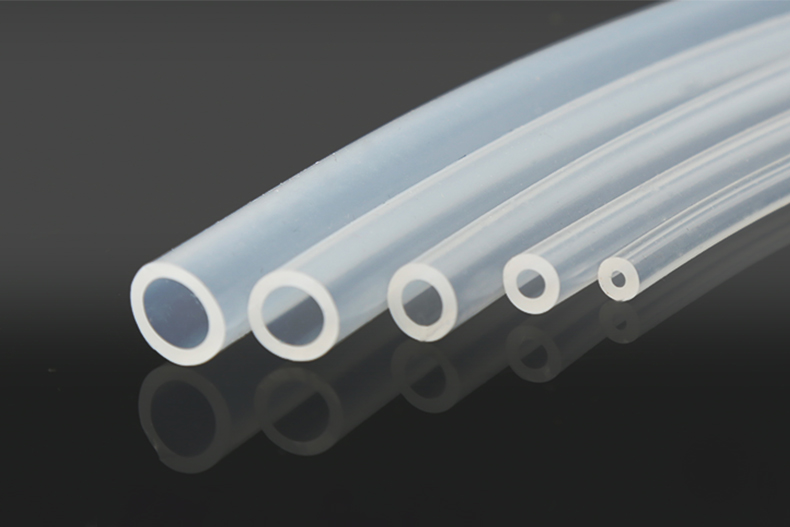

4. Size and Diameter:

Silicon tubes come in various sizes and diameters. Choosing the right size is straightforward but essential. Consider the inner and outer diameter of the tube in relation to the fittings and connectors you’ll be using. An uncomplicated match in sizes ensures that your connections are secure and free from leaks. Additionally, the length of the tube matters, so make sure you select a size that provides enough material for your project without excess wastage.

5. Regulatory Compliance:

Depending on your industry and application, there might be uncomplicated regulations and standards that you need to adhere to. Whether it’s the medical field, food industry, or any other sector, ensure that the silicon tube you choose complies with the relevant regulations. Look for tubes that meet industry-specific standards and certifications, ensuring that your usage is compliant and free from complications.

6. Chemical Compatibility:

The compatibility of the Rubber Diaphragms with the substances it will come into contact with is a straightforward yet crucial consideration. Different silicon formulations have varying degrees of resistance to chemicals, solvents, and other fluids. Make sure the tube is compatible with the specific substances in your application. Using an incompatible tube can lead to degradation, leaks, or other complications. Whether it’s in a laboratory, a manufacturing setting, or any other environment, the right chemical compatibility ensures your silicon tube performs reliably and without issues.

Silicon tubes may seem like straightforward components, but their importance in various industries cannot be understated. These uncomplicated considerations are crucial in ensuring that the silicon tubes you select are fit for your intended purpose, whether it’s in the medical field, the food industry, automotive applications, or DIY projects.