When it comes to the world of construction and road maintenance, nothing is as crucial as having the right tools for the job. Among these tools, the humble asphalt blade stands out as an essential element in achieving precision and efficiency in asphalt cutting and maintenance tasks. In this comprehensive guide, we will delve into the intricacies of Asphalt blades, exploring their types, applications, maintenance, and tips to ensure they remain in pristine working condition.

Types of Asphalt Blades

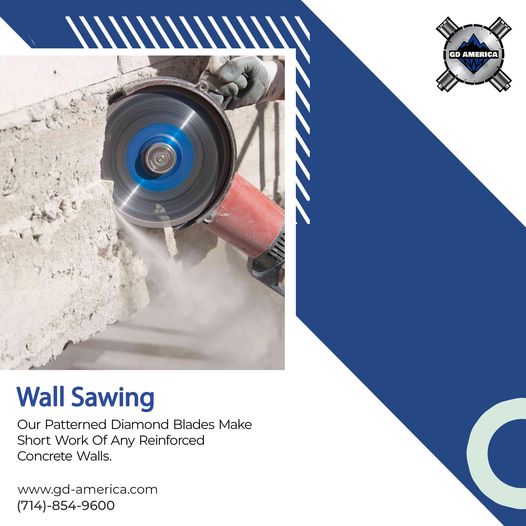

Diamond Blades: Cutting with Precision

Diamond blades are the unsung heroes of the asphalt cutting world. These blades are designed with a steel core and embedded diamond crystals. Their extraordinary hardness and durability make them ideal for cutting through asphalt and concrete like a hot knife through butter. Diamond blades come in various types, including segmented, turbo, and continuous rim blades, each designed for specific tasks.

Segmented Blades: Ideal for general-purpose asphalt cutting, they have segmented rims that provide a balance between speed and precision.

Turbo Blades: Designed for faster cutting, turbo blades have smaller gaps between the segments, resulting in quicker material removal.

Continuous Rim Blades: These are perfect for precision cutting. They feature a smooth, continuous rim that minimizes chipping.

Carbide Blades: Tough and Durable

Carbide blades are the go-to choice for heavy-duty asphalt cutting. They are made of tungsten carbide, which is known for its exceptional toughness and resistance to wear and tear. Carbide blades can cut through the toughest asphalt and are perfect for road maintenance projects.

Abrasive Blades: Affordable and Versatile

If you’re looking for an affordable and versatile option, abrasive blades are the way to go. These blades are made from a composite material, typically a combination of abrasive grains and a bonding agent. While they may not last as long as diamond or carbide blades, they offer excellent value for money and are suitable for occasional asphalt cutting tasks.

Applications of Asphalt Blades

Asphalt blades find applications in a wide range of construction and maintenance tasks:

Road Repairs: The most common use of asphalt blades is in repairing and maintaining roads. Whether it’s fixing potholes, resurfacing, or cutting expansion joints, asphalt blades are essential for achieving smooth and durable road surfaces.

Demolition: When roads or pavements need to be removed entirely, asphalt blades make the process efficient and controlled. They are essential tools for demolishing old asphalt surfaces.

Concrete Cutting: In some cases, asphalt blades are also used for cutting through concrete surfaces. Their versatility makes them a valuable asset in the construction industry.

Landscaping: Asphalt blades play a role in landscaping, helping to shape asphalt driveways, walkways, and parking lots to precision.

Maintenance Tips for Asphalt Blades

To ensure your asphalt blades remain in optimal condition and provide longevity and efficient cutting, follow these maintenance tips:

Clean After Use: After every use, remove any debris and asphalt residue from the blade to prevent damage and extend its lifespan.

Regular Inspection: Periodically inspect the blade for signs of wear and tear, including cracks, missing segments (for diamond blades), or dullness. Replace the blade if necessary.

Proper Storage: Store your asphalt blades in a dry, cool place to prevent rusting and deterioration.

Lubrication: Apply a thin layer of oil to the blade to reduce friction and enhance its cutting performance.

Sharpening: If you notice a decrease in cutting efficiency, consider sharpening or re-profiling the blade to restore its cutting power.

In Conclusion

In the realm of construction and road maintenance, the importance of a reliable Asphalt blade cannot be overstated. Whether you opt for diamond, carbide, or abrasive blades, the key is to choose the right tool for the task at hand and maintain it diligently.

Remember, quality asphalt blades are not just tools; they are your partners in achieving precise and efficient asphalt cutting. By selecting the right type of blade and following proper maintenance procedures, you’ll ensure that your projects run smoothly and your asphalt surfaces remain in top-notch condition.